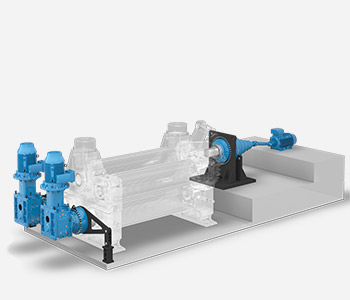

In recent years, there has been a shift towards using planetary gearboxes for sugar mill drive as an alternative to parallel shaft gearboxes. Planetary gearboxes for sugar mill drive are becoming increasingly popular due to their many advantages over their counterparts.

A planetary gearbox is a compact, powerful, and efficient gearbox that uses a planetary system of gears to transmit power. The gearbox comprises a sun gear, planet gears, and a ring gear. When power is transmitted through the sun gear, it is distributed evenly among the planet gears, which then rotate around the sun gear as they are held in place by the ring gear. With a planetary gearbox, the power transmitted gains better distribution, which makes it more efficient and effective.

So, what are the benefits of planetary gearboxes for sugar mill drive?

1. Higher mechanical rating: Planetary gearboxes have a much higher mechanical rating compared to parallel shaft gearboxes. This is because the power transmitted gets equally distributed amongst the gears, which means that each gear is responsible for transmitting lighter loads. As a result, the gearbox wears out much slower and has a longer lifespan.

2. Compact design: Planetary gearboxes are much smaller than parallel shaft gearboxes of the same power rating. This makes them ideal for sugar mills where space is limited. The compact design also means that there is less heat generated during operation, which further increases the efficiency and lifespan of the gearbox.

3. Improved efficiency: Planetary gearboxes for sugar mill drive have a significantly higher efficiency rate than parallel shaft gearboxes. This is due to their design, which ensures that there is less friction and power loss during operation. The higher efficiency also translates into lower energy costs and reduced carbon emissions.

4. Superior reliability: A planetary gearbox requires less maintenance and has a lower failure rate compared to parallel shaft gearboxes. This is because the planetary system distributes the load more uniformly, reducing wear and tear on the gears. The reduced maintenance and failure rate of planetary gearboxes make them more reliable and cost-effective in the long run.

5. Increased torque capacity: Planetary gearboxes have a higher torque capacity than parallel shaft gearboxes of the same size. This means that they can handle more load and transmit greater power, making them ideal for high-load applications such as sugar mill drive.

In conclusion, the use of planetary gearboxes for sugar mill drive offers a wide range of benefits over parallel shaft gearboxes. This includes improved efficiency, higher mechanical rating, superior reliability, and increased torque capacity. The compact design of planetary gearboxes also makes them ideal for limited spaces, reducing costs and saving energy. As sugar mills continue to enhance their processes, more and more mills are expected to embrace this innovative technology.